— Days-to-pay reduced from 60 + days to a 30 day average–

CORPUS CHRISTI, TX — Dirt Rocks, a leading aggregate logistics provider operating across Texas and Louisiana, significantly improved operational efficiency and cash flow by deploying TruckIT’s transportation and material management technology with E-Ticketing across its large-scale jobsite operations.

Dirt Rocks specializes in complex logistics for LNG (Liquefied Natural Gas) facilities and major infrastructure projects. The company manages material movement across hundreds of acres and,

on peak days, coordinates up to 400 trucks on a single job site. Legacy systems and manual paper ticket collection processes previously slowed on-site operations, invoicing, and extended payment cycles.

“At the scale we operate, cash flow lives or dies by how fast and accurate ticket data funnels from the field to the contractor,” said Jeremy Bell, President of Dirt Rocks.

“We had technology in place before TruckIT, but it was clunky and adoption in the field just wasn’t there. Without adoption, there are data gaps. We also found that in our experience the technology typically favored contractors to the detriment of haulers or the other way around. Now we have a tool delivering greater value for both sides with shared visibility.”

Before TruckIT, there was uneven adoption among independent haulers which meant Dirt Rocks was only able to actively manage a small portion of its projects digitally. Many jobs ran without real-time visibility, which slowed ticket reconciliation, work verification, and pushed days-to-pay to more than 60 days out.

TruckIT’s rollout changed Dirt Rock’s operations immediately. In just 10 days, Dirt Rocks was able to bring 17 projects online with their team and the haulers quickly adopting the technology due to its ease of use.

“Initially, we asked for a 45-day pilot,” Bell said, “but I think we only stayed on the pilot for 16 days. That’s how fast it clicked.”

Organizational Impact

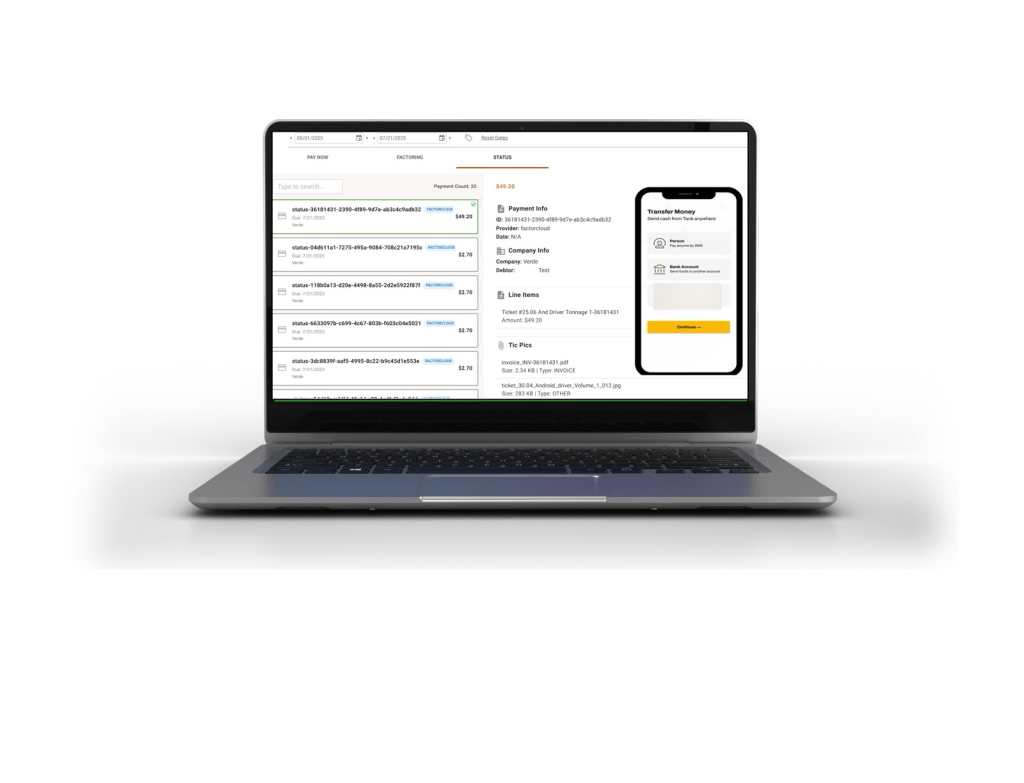

TruckIT digitizes tickets at the source and delivers accurate, contractor-ready business intelligence in real time. As a result, Dirt Rocks enhanced their service value to customers while shortening payment cycles and reducing working capital strain.

- AI powered E-Ticketing eliminated lost and inaccurate paper tickets

- Elevated user productivity and asset optimization lowered costs

- Days-to-pay reduced from 60 + days to a 30-day average

- Faster invoicing lead to more predictable cash flow

“The immediate value is the contractor having the data to better manage their daily production and pay faster,” Bell said. “When ticket data is clean and instantly accessible for everyone, cash moves faster.”

TruckIT’s throughput and product suite have positioned the company as a long-term, integrated partner for Dirt Rocks rather than just a software vendor.

Prior to co-founding TruckIT, CEO Andrew Lindsay’s construction company, Astra Group, built major infrastructure projects across the United States.

“I’ll suggest features all the time, but most of the time they’ve beaten me to it.” said Bell. “That’s how advanced the TruckIT platform is.”

According to Dirt Rocks, that level of industry foresight and responsiveness reflects a platform designed by people who understand the realities of the job site.

“TruckIT has a deep understanding of how contractors actually operate, and that shows up in the product,” continued Bell.

TruckIT’s thoughtful design and advanced geofencing allow Dirt Rocks and it’s customers to track truck and material movement across massive job sites with precision. Sub-geofences within a single project provide granular visibility into specific delivery zones and stockpiles. Contractors use that insight to reduce congestion by better coordinating crews and equipment.

“If I’m a superintendent and know a truck or trucks have breached the gate and within a few hundred yards of me, that changes everything,” Bell said. “With that information, I can relieve congestion, reduce equipment tension, and keep the job moving by being prepared for what’s coming.”

Data That Drives Better Decisions

Dirt Rocks also relies on TruckIT’s analytics and reporting to optimize loader utilization, manage pit balance, and plan rail operations.

“We use the live feeds to run our rail plans,” Bell said. “We know when a truck will be back, how long it sat at the loader, and how long we need to run our equipment. Having that level of data and not having to guess directly impacts cost and cash.”

Rapid Adoption, Minimal Support

TruckIT’s intuitive, bilingual interface drove rapid adoption across broker-driven and highly fragmented markets.

“It’s incredibly easy for haulers,” Bell said. “They’re collecting their own tickets as fast as we are, and it requires very little support. That’s why adoption took off.”

A Platform Built for Heavy Construction

TruckIT’s ongoing innovation, driven by advances in artificial intelligence coupled with its industry-first design, is a game-changer for their customers.

About Dirt Rocks

Dirt Rocks is an aggregate logistics provider operating five rail yards along the Gulf Coast of Texas and Louisiana, with additional sand and gravel pits in Texas. The company specializes in high-volume, high-complexity logistics for LNG facilities and large-scale infrastructure projects. Visit www.dirtrocks.com.

About TruckIT

TruckIT is a cloud-based technology company with web and mobile applications that automates, digitizes, and optimizes the heavy construction material supply chain by streamlining error prone and manual tasks that drives efficiency for owners, contractors, truck brokers, haulers, DOT’s, and material producers throughout the US, South America, and Canada. Visit www.truckIT.com.