When you’re running hundreds of dump trucks, cash flow can make or break your business.

One Choice Logistics out of Davie, Florida, found that out the hard way.

They were growing fast, more trucks, bigger contracts, more invoices, but those same 60- to 90-day payment terms were choking their cash flow.

Instead of slowing down, they teamed up with TruckIT and Bolton Capital to turn finished jobs into paid invoices in as little as 48 hours.

The Challenge: Growing Fast, Waiting Even Longer

Like most hauling companies, One Choice Logistics built its reputation the right way by showing up, getting the job done, and paying drivers on time. But as the business took on bigger projects across South and Central Florida, the numbers started working against them.

Weekly payroll, monthly material bills, and 60–90 day customer payments created a serious cash crunch. They were stuck floating hundreds of thousands in receivables while still keeping 250 owner-operators rolling.

“We pride ourselves on paying our drivers and subs on time, every time,” said CEO Azohani “Nani” Bernal. “But the bigger the contracts we won, the tighter our cash flow got. It was stressful trying to keep everyone paid while waiting on checks.”

That story’s not unique, in construction, you can be profitable on paper and broke in real life if your money’s tied up in invoices.

The Solution: Turning Jobs Into Cash in 48 Hours

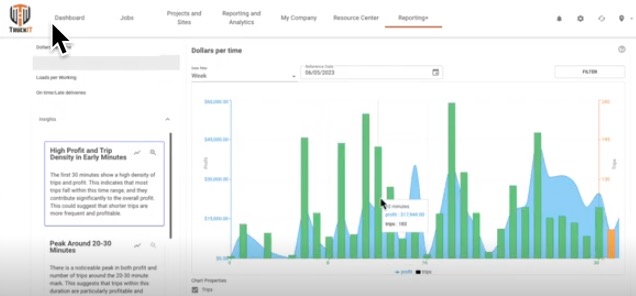

One Choice turned to TruckIT, the market leader in digitizing and optimizing the bulk hauling supply chain, and its financial partner, Bolton Capital. Together, they built a system that keeps cash moving as fast as the trucks themselves.

Here’s how it works:

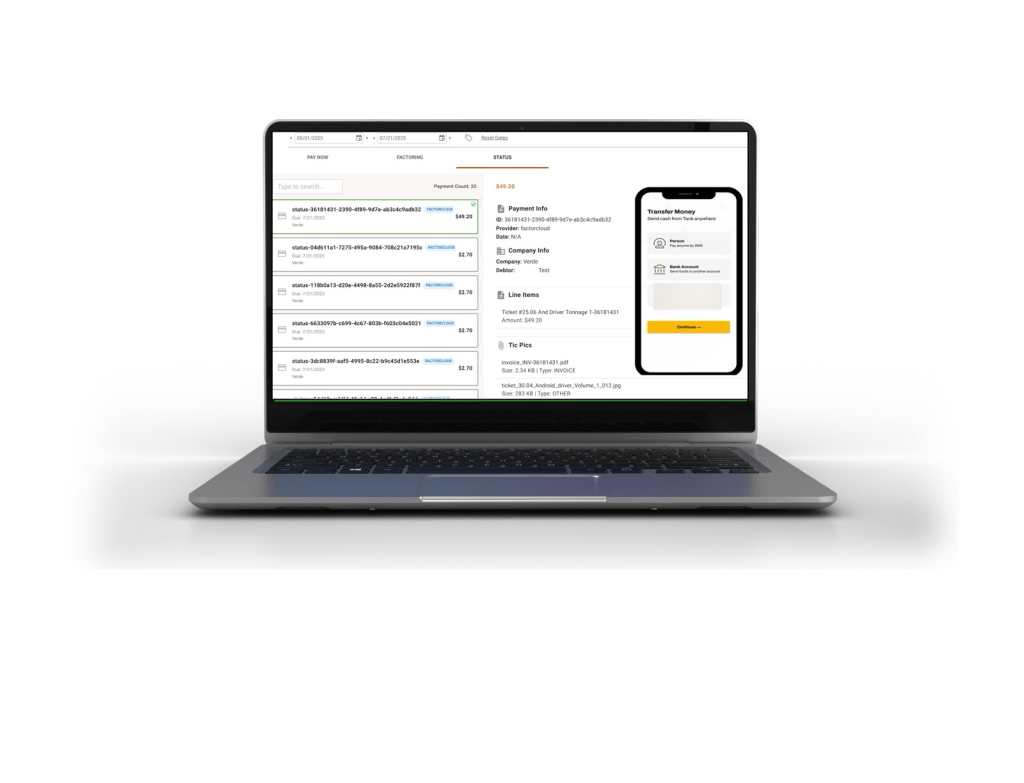

- Drivers complete a job and log the e-Ticket through TruckIT’s digital platform, no paper, no lost tickets.

- Those verified tickets are automatically matched to invoices.

- Bolton Capital reviews and funds the verified invoices — sometimes in less than two business days.

In one week alone, One Choice submitted $600,000 in invoices through the TruckIT platform. Bolton funded $400,000 in 48 hours, and the remaining $200,000 the following Monday.

That simple change, going from paper tickets and long waits to verified digital records and same-week pay, completely flipped the script for their business.

“Bolton and TruckIT helped us change the game,” said Bernal. “They’re part of our team now, helping keep our drivers, subcontractors, and customers paid and happy.

The Results: Stronger Cash Flow, Happier Drivers

Once One Choice connected TruckIT and Bolton Capital, the difference was immediate.

Cash flow stabilized. Instead of waiting 60 to 90 days for customer payments, money started hitting their account within 48 hours of job completion. That gave them the breathing room to take on more work without worrying about payroll.

Drivers got paid on time, every time. That reliability built loyalty across their 250-truck network, keeping good haulers behind the wheel and reducing turnover.

Back-office stress disappeared. No more chasing paper tickets, no more manual reconciliations. TruckIT’s digital e-Ticketing made invoicing clean and fast, while Bolton’s funding kept the operation running smoothly.

“For six months, I was stressed out 24/7 about making payroll,” said Bernal. “Now, I can breathe. TruckIT and Bolton made my life easier.”

CEO Andrew Lindsay of TruckIT summed it up well:

“Through our partnership with Bolton, we’re not just improving efficiency, we’re helping haulers like One Choice run their business effectively and strategically.”

How You Can Keep the Cash Flowing Too

If you’re in the hauling business, you know this story all too well.

You finish the work, your drivers are waiting on pay, and your customers are sitting on your money.

TruckIT and Bolton Capital built a simple, practical solution to that problem:

Digitize your operations. Verify every load. Get paid faster.

With TruckIT’s e-Ticketing, optimized dispatching, and invoice automation, your paperwork moves as fast as your trucks. And with Bolton Capital’s same-day funding, you can stop sweating payroll and start planning your next big job.

Whether you run ten trucks or two hundred, you deserve the same kind of peace of mind that One Choice Logistics found.

👉 Take the hassle out of hauling, and the stress out of payments.

Book a free TruckIT demo today.

Want to read the full story?

Check out the original feature on CityBiz: “Bolton Capital and TruckIT Keep the Cash Flowing for One Choice Logistics.”