Changing the Way We Think About Building

At this year’s Dirt World Summit, one message came through loud and clear: the construction industry is ready for change.

Aaron Witt challenged us to stop relying on outdated systems and habits that hold us back (read more about that in The State of the Dirt World: Why Now Is the Time to Evolve). But that change doesn’t start with new tools alone. It starts with the way we think and lead.

Some of the Summit’s most powerful lessons came from outside the industry, from people who know what it means to break convention, challenge comfort, and lead by example. Their ideas all come down to one thing: if we want to build a stronger dirt world, we have to lead it differently.

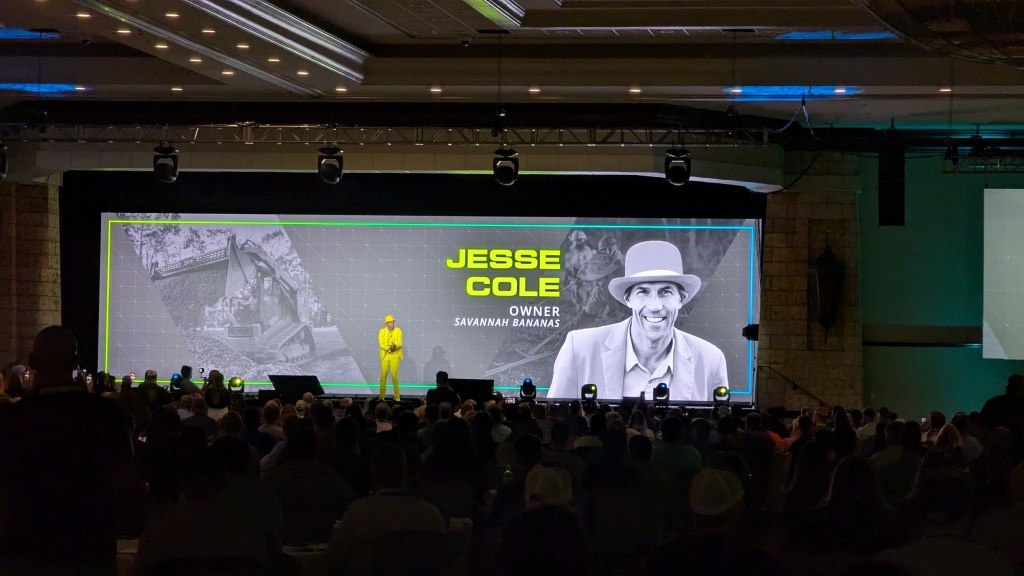

Learning from the Unlikely: Jesse Cole and the Power of Experience

Jesse Cole, founder of the Savannah Bananas, built something that most people thought was impossible, turning a small-town baseball team into one of the most talked-about organizations in sports. He did it by throwing out the rulebook and focusing on people instead of the product.

His “5 E’s to Creating Raving Fans” fit surprisingly well in construction:

- Eliminate Friction: Find the pain points in your process, for your customers, your drivers, and your crews, and remove them.

- Entertain Always: People remember how you make them feel, not just what you deliver. Show your customers and your team that their experience matters.

- Experiment Constantly: Try new ways of doing business. Not everything will stick, but the things that do can transform your operation.

- Engage Deeply: Build real relationships with your partners and your people. Pick up the phone, show up, and keep communication open.

- Empower Action: Give your team ownership. Recognize effort. Let good ideas come from anywhere.

Cole’s story is a reminder that progress doesn’t come from comfort. His team failed plenty of times before they found what worked. But by experimenting and listening to their audience, they built something stronger.

That same spirit applies to construction. The best companies in the dirt world are finding ways to make their work easier, safer, and more enjoyable for their people and their customers. It’s about removing friction, not adding more.

When you give your people better tools and systems, you’re not just improving efficiency — you’re creating a better experience for everyone involved in the job. That’s how you build loyalty, attract talent, and keep the next generation excited about this industry.

Tim Grover: Leading with Relentless Discipline

Tim Grover, coach to some of the greatest athletes in history, including Michael Jordan and Kobe Bryant, spoke about the mindset that separates the good from the great. His message wasn’t complicated: discipline and discomfort go hand in hand.

Grover talked about how true leaders demand more from themselves than anyone else possibly could. They don’t wait for perfect conditions. They show up, they work, and they push their limits every single day.

That mentality applies directly to leadership in construction. Whether you’re managing a crew, running a company, or dispatching trucks, the work is never easy. But growth doesn’t come from doing what’s easy; it comes from doing what’s necessary.

Leadership isn’t about barking orders or working longer hours. It’s about setting the standard. It’s showing your team that you’re willing to do the hard things, learn new systems, take responsibility for mistakes, and push through the tough days.

Grover’s message ties right back to what Aaron Witt said at the Summit: comfort is holding the industry back. The leaders who will drive this industry forward are the ones willing to get uncomfortable, to admit when something isn’t working, to try a new approach, and to demand better from themselves and their teams.

Discipline isn’t just a personal trait; it’s the foundation for accountability, safety, and trust. When crews see leadership that practices what it preaches, they follow suit.

James Clear: Small Changes, Big Results

James Clear, author of Atomic Habits, focused on how lasting progress happens, not through huge changes overnight, but through small, consistent improvements stacked over time.

Clear’s “Four Laws of Behavior Change” offer a practical roadmap:

- Make it Obvious: Create an environment where the right habits are hard to miss.

- Make it Attractive: Tie new habits to things that are rewarding or meaningful.

- Make it Easy: Start small and remove barriers to action.

- Make it Satisfying: Celebrate small wins so the team sees the payoff.

For construction leaders, this means looking at daily operations through a new lens. Want to cut back on errors? Start by digitizing one part of your process, maybe tickets or dispatching, and build from there. Want better communication? Set up simple, consistent check-ins between the field and office before adding more systems.

Clear’s point matches what Aaron Witt and Tim Grover both said in their own ways: real improvement takes commitment, not convenience. It’s the small steps, taken consistently, that transform a company’s culture and performance over time.

When you focus on steady progress instead of perfection, you build momentum. And in this industry, momentum is everything.

Putting It All Together

Taken together, the lessons from Dirt World 2025 form a clear picture of what the next phase of this industry needs to look like.

- From Aaron Witt: Stop clinging to outdated methods.

- From Jesse Cole: Focus on people, not just projects.

- From Tim Grover: Embrace discomfort and lead by example.

- From James Clear: Build better habits, one step at a time.

This industry is built on hard work and persistence. Those values haven’t changed, but how we support that work has to. The future belongs to companies that care about their people, remove friction, and adopt new tools that make the job better for everyone involved.

Technology, mindset, and leadership aren’t separate conversations; they’re all part of the same one. The way we lead determines the way we build.

Where TruckIT Fits In

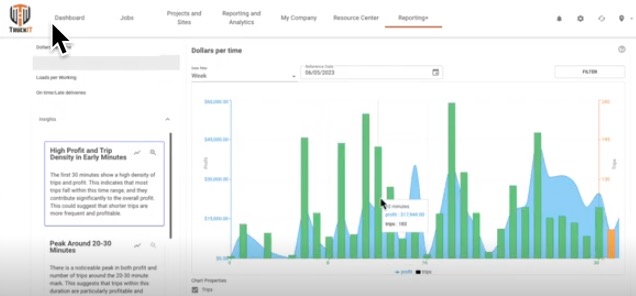

At TruckIT, we see this shift happening every day. The companies finding the most success aren’t just buying new tools; they’re building new habits. They’re taking the time to train their people, streamline communication, and focus on consistency.

Our job is to make that process easier. TruckIT helps teams remove friction from the day, automating dispatching, digitizing tickets, and connecting the field and office in real time. It’s the same philosophy that every great speaker at Dirt World preached: simple, steady improvement that frees up your team to focus on what matters.

We’re proud to be part of an industry that’s learning, adapting, and leading from the front.

Change doesn’t happen overnight; it happens load by load, day by day. Let’s keep building it together.

If you missed Aaron Witt’s message about the state of the industry, read The State of the Dirt World: Why Now Is the Time to Evolve.