At TruckIT, we’ve always believed in pushing boundaries and driving change in an industry that is often slow to embrace new technologies. Today, we’re thrilled to announce that our hard work and innovation have been recognized in a big way. TruckIT has been named to the prestigious 2025 FreightWaves FreightTech 100, and we are incredibly proud to be the ONLY construction tech company on the list!

What is the FreightTech 100?

The FreightTech 100, compiled by FreightWaves, recognizes the most innovative and disruptive companies in freight technology each year. From transportation to logistics, the companies named to this list are transforming how goods move across the globe. Being included in this elite group highlights the innovation and forward-thinking vision of TruckIT in a traditionally siloed industry.

But what makes this even more special? We’re the only construction-focused tech company to make the cut. While many other industries have already seen massive tech overhauls, the construction world has been slower to adopt, leaving plenty of room for growth. We’re changing that.

Why TruckIT Stands Out

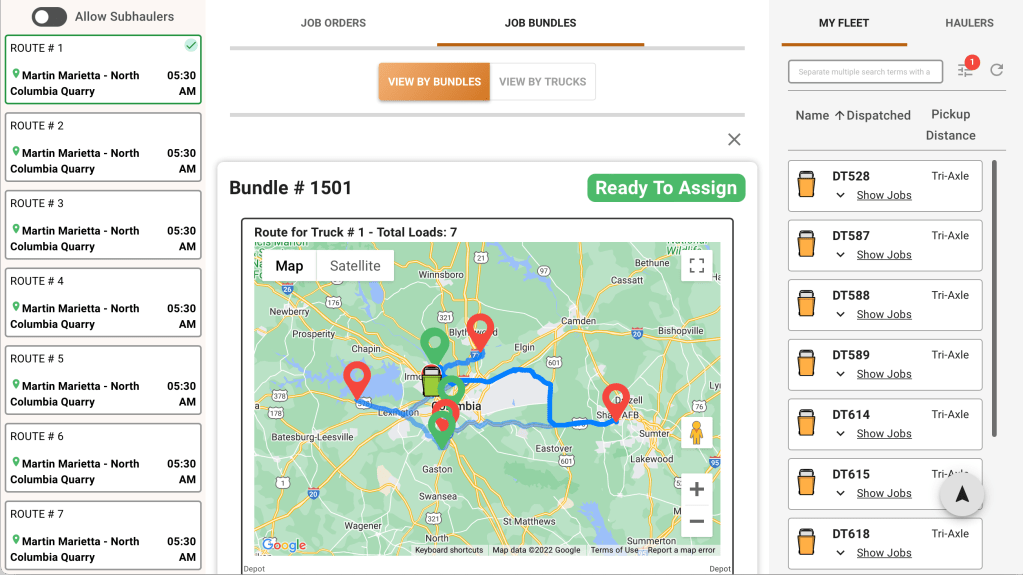

Construction and freight are two industries that often operate in parallel, but rarely intersect as smoothly as they should. TruckIT bridges that gap, offering construction companies a streamlined, tech-forward solution to manage the logistics of material hauling with precision and ease. From project management to real-time load tracking and digital ticketing, we’ve simplified what can be a frustrating and complex part of the construction process.

- Real-time logistics: We bring full visibility to construction material transportation, reducing downtime and maximizing efficiency.

- Cost-effective operations: With better tracking and job coordination, our clients are saving both time and moneyf while benefitting from heightened productivity.

- Innovation in construction: As the only construction tech company on the FreightTech 100, we’re leading the charge to bring cutting-edge technology to job sites nationwide.

What Does This Mean for the Future of Construction?

At TruckIT, we’re committed to continuing our mission of innovation and disruption in the construction industry. As we expand, our technology will only get better, our service more refined, and our impact on the construction world more profound.

We’re incredibly proud of this recognition, but we’re even more excited for what lies ahead. Being included in the FreightTech 100 for 2025 is proof that the future of construction logistics and material management is here—and TruckIT is leading the way.

Thank You to Our Partners & Customers

Our partners and customers have led us here and their trust and belief in TruckIT has allowed us to continue to break new ground. Together, we’re building a future where construction is faster, smarter, and more efficient than ever before.

Join Us on the Journey

If you’re ready to take it to the next level, join us on this exciting journey. Here’s to achieving many more milestones!

🚀 Stay tuned for more exciting news from TruckIT!

https://www.freightwaves.com/news/freightwaves-announces-2025-freighttech-100-companies

#TruckIT #FreightTech100 #ConstructionTech #FreightWaves #InnovationInConstruction #TechInConstruction #FutureOfFreight